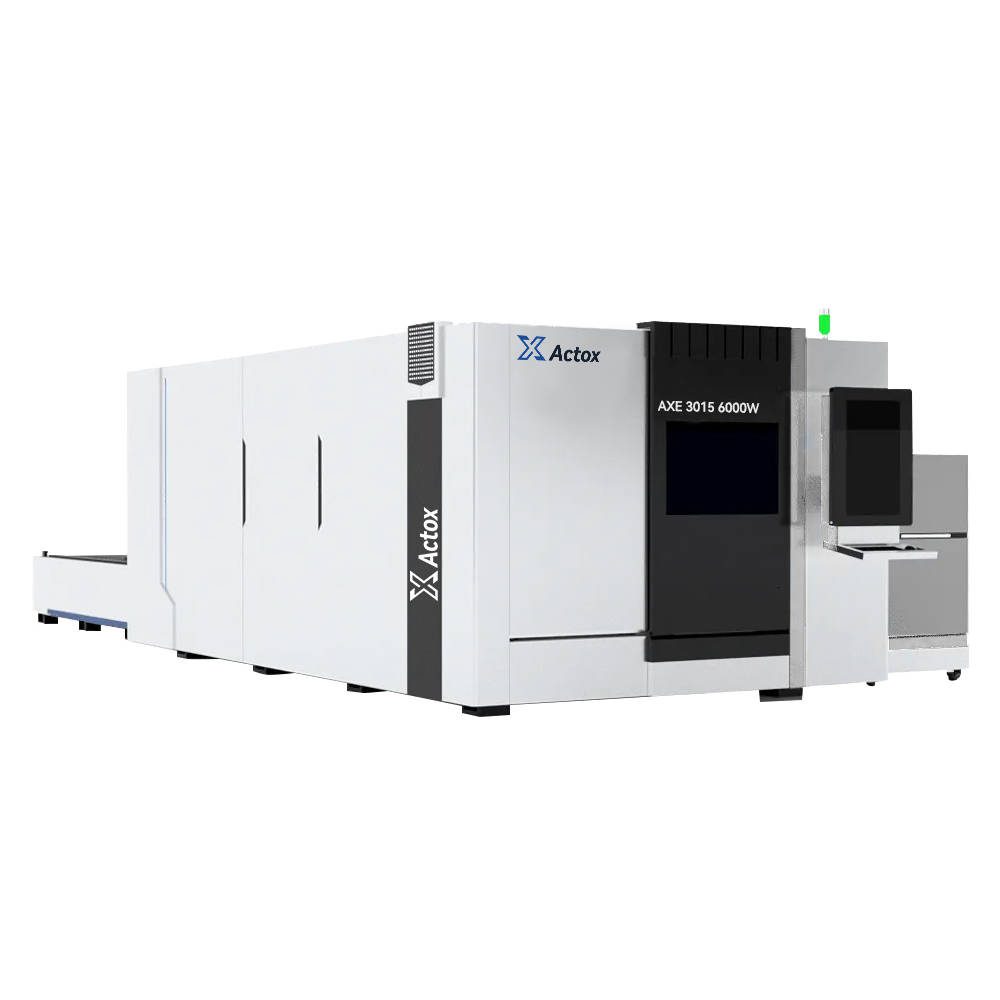

Electro-hydro CNC Press Brake

Electro-hydro CNC Press Brake

1.Model: AXPB Series

2.Optional CNC system Delem, ESA, Cybelec.

3.Digital Programmaing, 2D/3D graphical Touch system optinal

4.Different Axis fully automatic controlled (Y1,Y2,Z1,Z2,X1,X2,R1,R2,V)

5.Servo motor control for high bending accuracy

6.Higher bending efficiency, and the bending times are increased by at least

30%

7.Capacity 30Ton-3000Ton

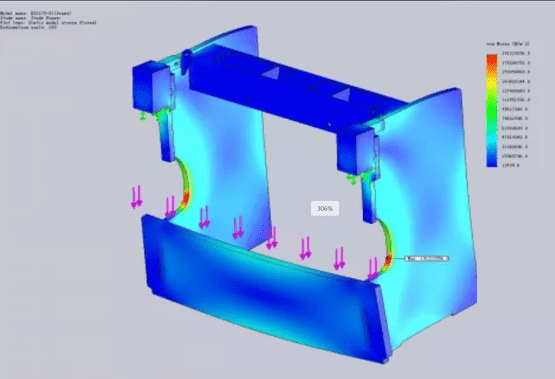

FEA & Stress Analysis

CAE software and SOLIDWORKS are used to analyze the linear static structure, stress and deformation of the press brake and laser cutting machine frames. Therefore, for complex structures, highly complex loads, transient modeling and the combination of the above two.

CNC Control System

The controllers are three well-known brands worldwide: Delem, ESA and Cybelec. These controllers are imported from the Netherlands, Italy and Switzerland respectively.

The efficient algorithm optimizes the bending cycle, reduces the setup time of the work steps, and improves the overall efficiency of the bending process, especially in batch processing scenarios.

In addition, the system can accommodate both 2D and 3D graphics editing.

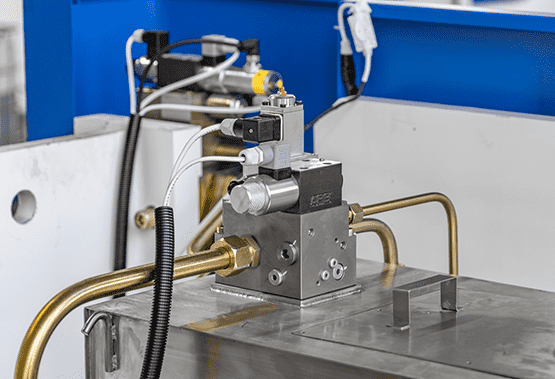

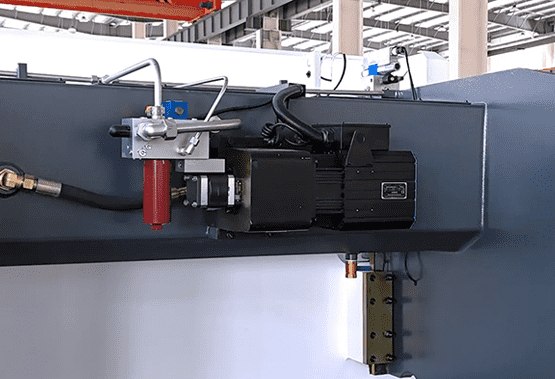

Hydraulic System

Adopting German Rexroth fully closed-loop electro-hydraulic servo high-frequency synchronous control system, it ensures that the machine tool has high stability and high precision during high-speed operation.

Advantages:

The frequency response (response frequency) is high, up to 200Hz.

It can continuously and proportionally control the pressure and flow of the hydraulic system, control position, speed, force, and reduce the impact of pressure changes.

Closed-loop control, signal feedback.

Original German imported products, longer service life.

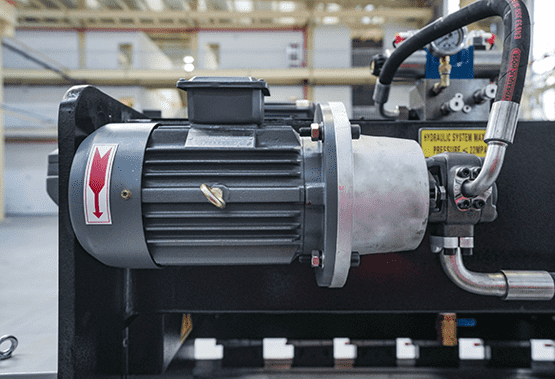

Main Motor--AC motor

The main motors have the characteristics of high efficiency and energy saving, large starting torque, excellent performance, low noise, low vibration and high reliability. The power and installation dimensions of these motors meet IEC standards and are easy to use and maintain.

The power and voltage of the main motors can be customized according to the specific voltage requirements of the customer’s region.

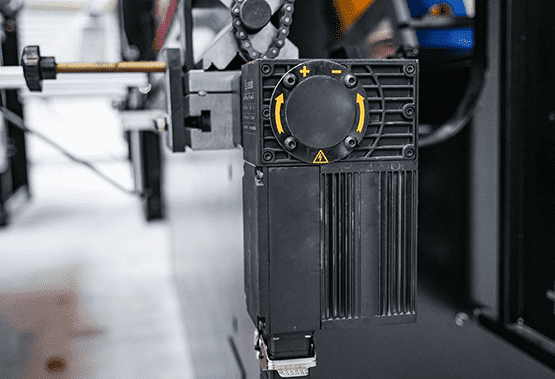

Serve Motor (optional)

Servo motors improve machine productivity with low energy consumption. If the machine is not working, the servo motor will not consume energy. Compared with traditional motors, the use of servo motors can save up to 35% of energy, thus bringing customers the benefits of improved efficiency and reduced operating costs.

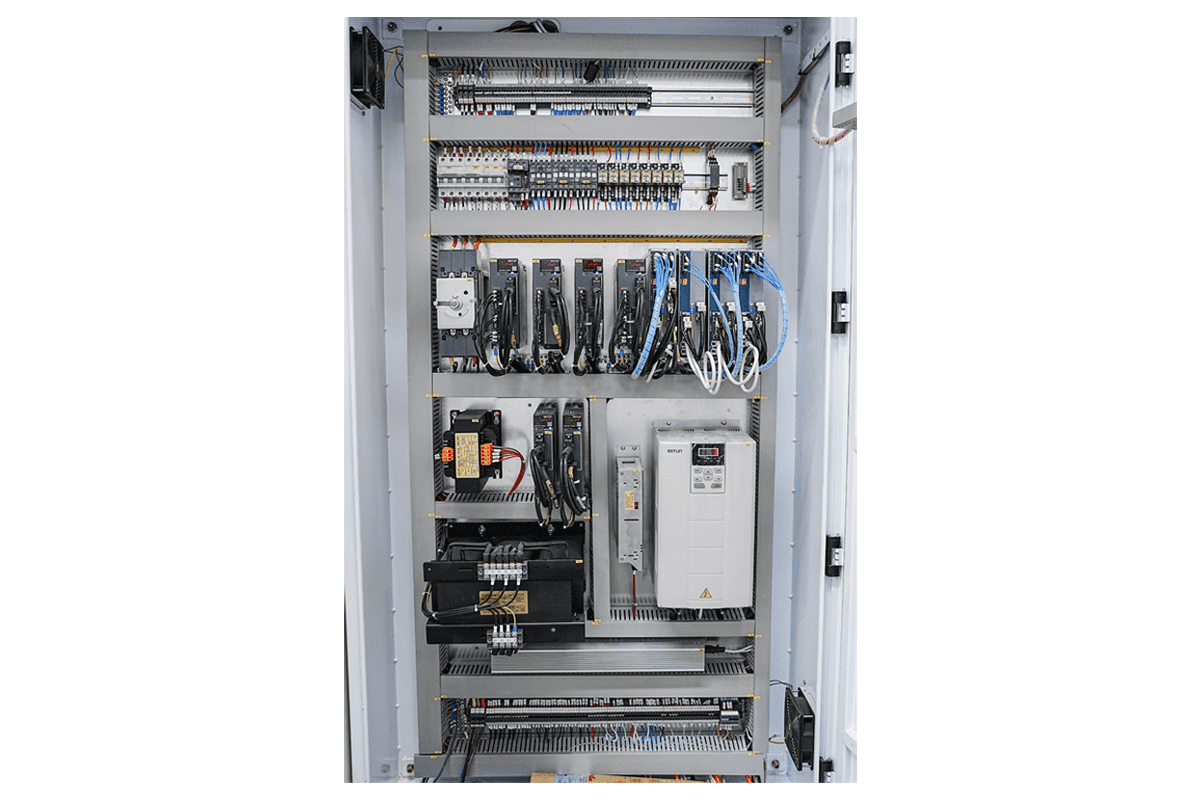

Electrical Components

The electrical components are imported or Sino-foreign joint venture products, which meet international standards, are safe and reliable, have a long service life, and have strong anti-interference ability. The electrical cabinet is equipped with a heat dissipation device.

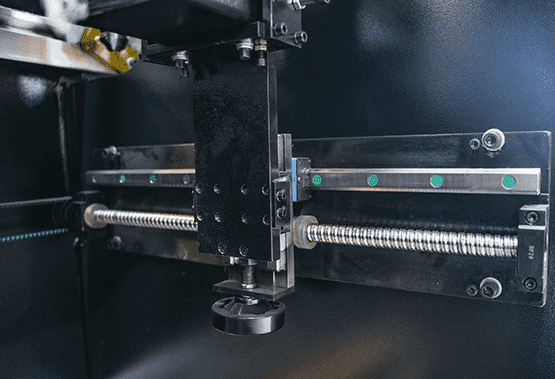

Stable And Reliable Backgauge

The high-precision back gauge assembly is developed and produced by our company. It is equipped with a high-precision ball screw, adjustable back gauge finger, and manual lifting function, which can adapt to a variety of different molds and bending requirements.

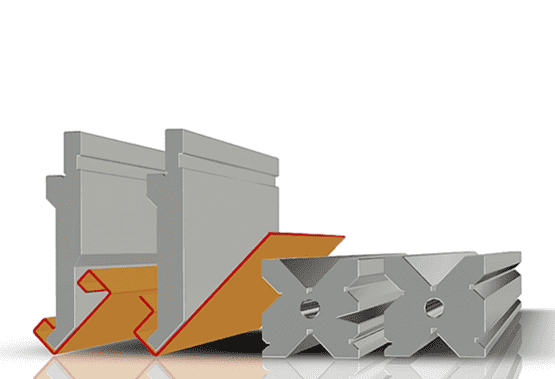

Punches & Dies

Punches and dies for hydraulic bending machines are one of the most important topics. Different punch and die combinations can complete bending of any shape. We can design and produce suitable punches and dies according to different bending requirements of customers.

Crowning Table

The electric mechanical crowning table has high control accuracy, and the compensation amount is automatically calculated and set by the CNC system to ensure the consistency of the bending angle over the entire length.