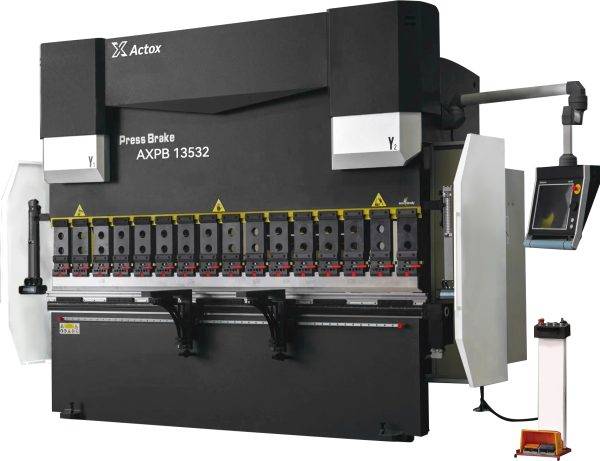

Torsion-sync Economic NC Press Brake

Torsion-sync Economic NC Press Brake

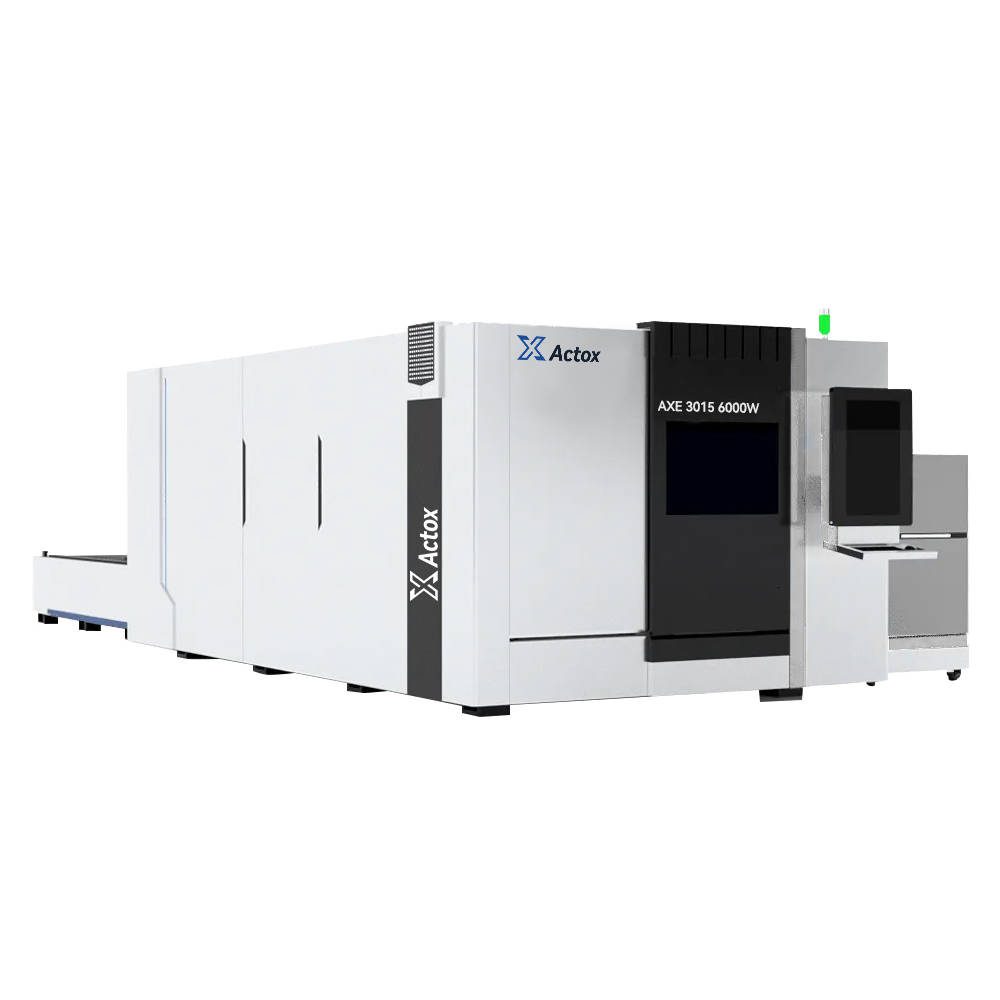

1.Model: AXK Series

2.Optional NC system: E21/ E22/ TP10S

3.Tosion Bar Structure , include the Y and X axis , AC motor control

4.Manual worktable crowing optional Semi-auto manual operation

5.All keys on the panel are micro-switches

6.Capacity 30Ton-600Ton

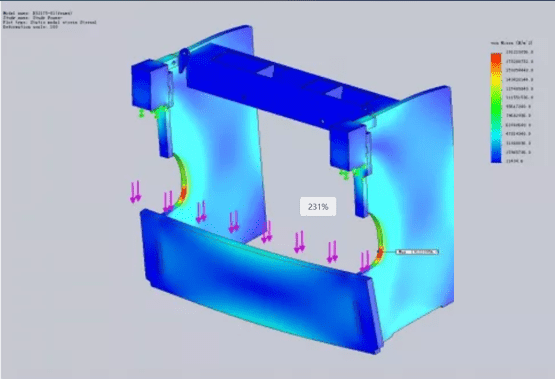

FEA & Stress Analysis

CAE software and SOLIDWORKS are used to analyze the linear static structure, stress and deformation of the press brake and laser cutting machine frames. Therefore, for complex structures, highly complex loads, transient modeling and the combination of the above two.

NC Control System

ESTUN E21 Control

Backgauge control

Control the common motor or inverter

X&Y-axis intelligent positioning

Multi-step programming, 40 programs, each program 25 steps

Built-in time relay function

Chinese and English

Metric system

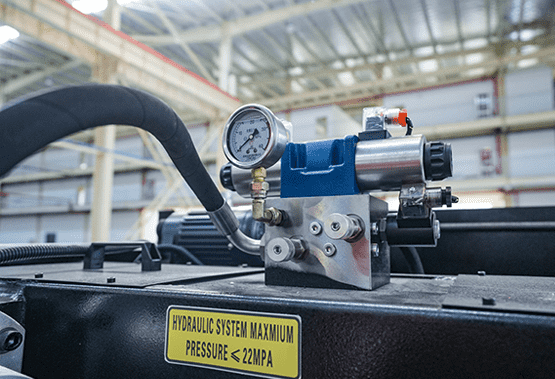

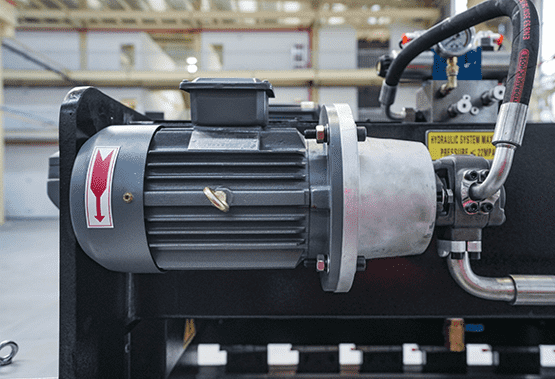

Hydraulic System

High-quality hydraulic valves such as Rexroth, these valves can withstand high pressure, are durable, and require minimal maintenance.

It can ensure that the machine can complete the activities of fast descent, slow descent, bending at working speed, fast return and plunger emergency stop.

The machine can work continuously under rated load, the hydraulic system maintains stability and precision, and is completely leak-free

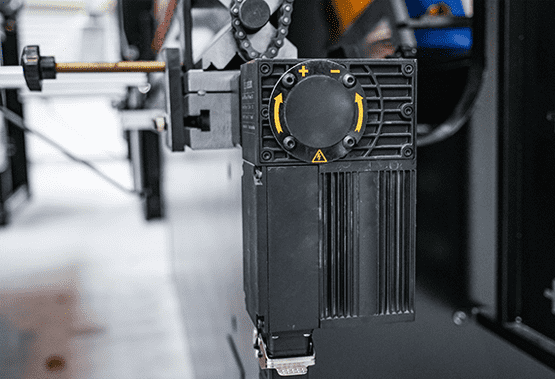

Main Motor

The main motors have the characteristics of high efficiency and energy saving, large starting torque, excellent performance, low noise, low vibration and high reliability. The power and installation dimensions of these motors meet IEC standards and are easy to use and maintain.

The power and voltage of the main motors can be customized according to the specific voltage requirements of the customer’s region.

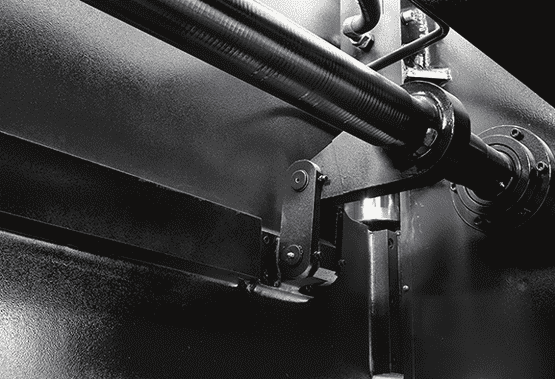

Torsion-sync Bar

The torsion axis synchronization principle controls the slider to move up and down for bending

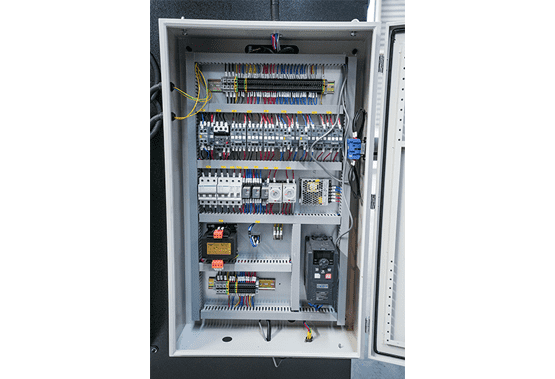

Electrical Components

The electrical components are imported or Sino-foreign joint venture products, which meet international standards, are safe and reliable, have a long service life, and have strong anti-interference ability. The electrical cabinet is equipped with a heat dissipation device.

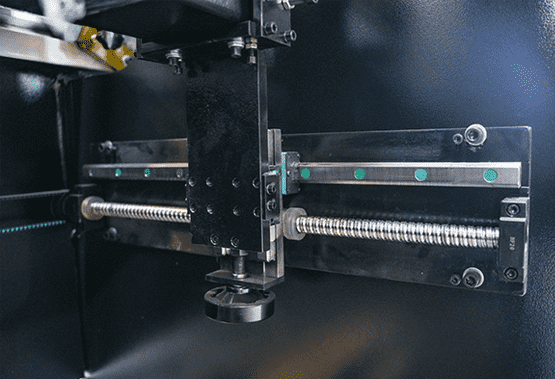

Stable And Reliable Backgauge

The high-precision back gauge assembly is developed and produced by our company. It is equipped with a high-precision ball screw, adjustable back gauge finger, and manual lifting function, which can adapt to a variety of different molds and bending requirements.

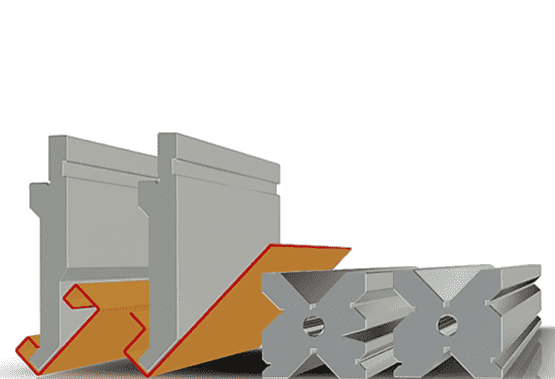

Punches & Dies

Punches and dies for hydraulic bending machines are one of the most important topics. Different punch and die combinations can complete bending of any shape. We can design and produce suitable punches and dies according to different bending requirements of customers.

Crowning Table

The electric mechanical crowning table has high control accuracy, and the compensation amount is automatically calculated and set by the CNC system to ensure the consistency of the bending angle over the entire length.